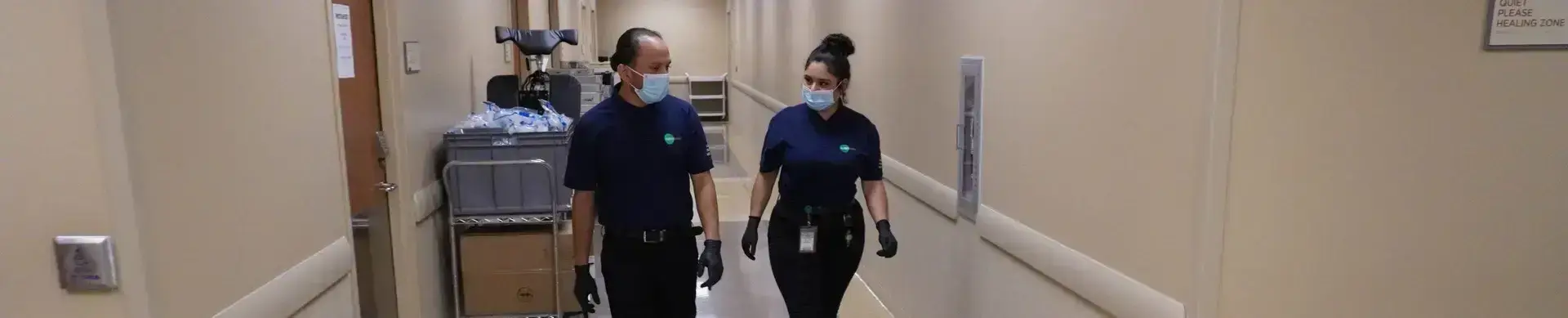

Expert teams with safety training, industry-specific recommendations, and flexibility to support operations without disrupting production or your bottom line.

Steve Strzok, Facilities and Global Engineering Services Manager at Rockwell Automation

The activity of removing dirt and impurities from surfaces, objects and environments.

Chemical process that lessens the number of germs on surfaces to make them safe for contact.

Thorough full-surface disinfecting that adheres to EPA kill/dwell times. This always follows a complete cleaning and sanitizing cycle.

A process that solely focuses on disinfecting door knobs, handles, touch-plates, handrails, elevator buttons, telephones, restroom surfaces, etc., in common spaces and facility-wide.

EPA-approved solutions are needed to completely eliminate germs. Hospitals use disinfectants in areas with body fluids, requiring extreme disinfecting to prevent pathogen spread.

Every cleaner who accepts our offer of employment is required to complete an on-line training program that outlines our expectations and ongoing resources. This is in addition to ongoing in-person training.

"At our company, the safety and health of our employees is by far our biggest focus. As we attempted to navigate through the current pandemic, we needed a team of professionals we could rely on to help us ensure we were making the right decisions when it came to protecting our employees’ health and well-being. KleenMark was that team!"

Bales

Safety Director / Operations Director, Cornerstone Construction

"Kleenmark has more than exceeded our expectations during the COVID-19 Pandemic. They have always been trusted and valued partners of ours, but after seeing their response and attention to detail during this challenging time, we have an even greater respect for them as a game-changing leader in their industry."

Tara Saleh

Director of Business Development and Communications, MIG Commercial Real Estate

"KleenMark’s cleaning teams have the additional training and certification that gave me the reassurance they could quickly and effectively disinfect our headquarters. They backed that up with an attention to detail and thoroughness that sets them miles apart from others."

Noah R.

ETE REMAN

"KleenMark have established. It is especially welcomed during this difficult time and the effort you and your team have put in to respond promptly to changing needs and requests has been outstanding."

Russel Reszel

Senior Manager, Facilities Services, Exact Sciences

"Thank you all (at KleenMark) for being nimble and accommodating of our post-construction clean."

Randy Smith

Facilities Architect, University of Wisconsin School of Medicine and Public Health