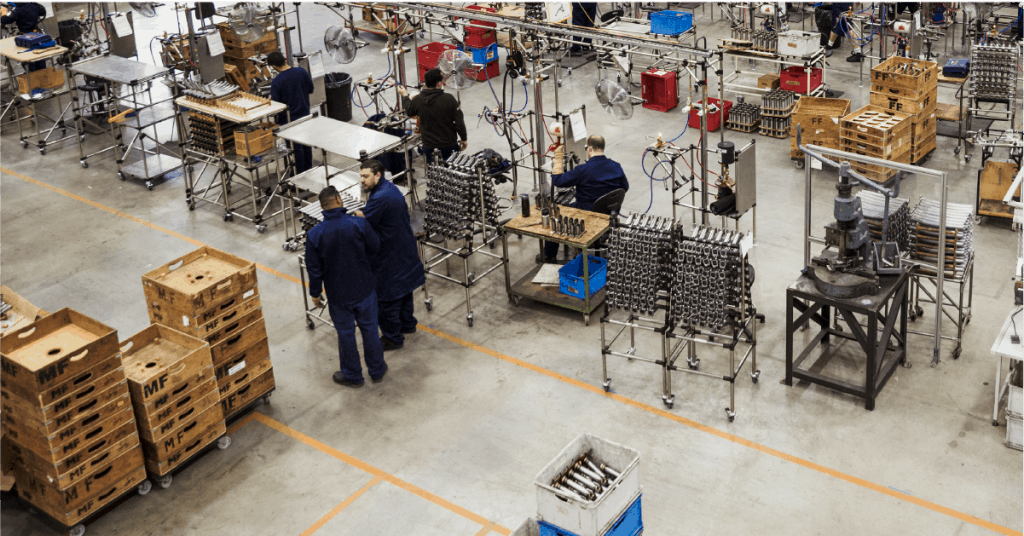

A clean floor that’s properly maintained is a safe floor. Aesthetics aside, that’s a significant reason to make factory floor care a priority.

Now, you may be thinking, “We require personal protective equipment, including anti-slip shoes, in all our plants. What’s a little dust or oil spill?” Well, it adds up quickly – and it will quickly become a hazard.

But, a solid floor-care program can make your facility safer and protect your floors. Addressing both issues means you reduce the risk of costly down time that’s the result of accidents and repairs.

Build Your floor-care Program

A factory floor-care program has several components. Each serves a specific purpose, and each should be implemented on various schedules. Of course, you may need to tweak the frequency depending on your industry’s specific needs.

Daily scrubbing.

Use a walk-behind or ride-on scrubber to clean your floors daily. Use a commercial degreaser, which will remove any surface residue that’s built up on the floor. Consider this your most important step for maintaining your factory floor.

Add heavy-duty degreaser/number of daily scrubs.

If you manage a plant that handles a lot of oils and lubricants, consider using a heavy-duty degreaser each day. Additionally, schedule your floor scrubbing for at least two times daily or between every shift. This will keep oils from soaking into your floor or becoming difficult to remove.

Seal your concrete, tile and grout.

Remember, concrete is porous. If you don’t seal it, you’re not getting all the liquid out/off of it, even when scrubbing daily. Over time, that liquid will break down the concrete. You’ll have to cut out the bad concrete and replace it. That’s expensive and could lead to downtime.

Heavy-duty cleaning.

At least quarterly, have your cleaning company perform a heavy-duty floor scrub. Consider it the scouring pad, while daily scrubbing is the sponge. Using a more aggressive swing machine will better penetrate the concrete’s pores. These machines move slowly and it’s a more involved process, so it’s generally done less frequently and during third shift. At this time, we often strip the sealer first and then reapply after the heavy-duty cleaning.

Don’t Forget the Mop

I know, old school, right? But it’s the essential tool every factory floor care program needs. Why? If you’re facility is prone to having a lot of spills, a mop will absorb more than 80 percent of the spill if addressed immediately. Combine that with a daily scrubber and you have the foundation for an effective program.

Curious what your facility’s program would look like, or just have a related question? Send us a note any time.